There's a system that's utilized for recalibrating a Resource and it is recognized as bench calibration. It is actually a very important approach that should http://edition.cnn.com/search/?text=calibration be performed as a way in order that each of the parts of a Resource are operating thoroughly. If a Instrument is not really correctly re calibrated, it can cause inaccurate measurement. This may result in a variety of complications.

Fundamental procedure

There are many ways associated with the whole process of recalibrating a tool. Calibration entails evaluating an instrument's output having a reference instrument's. This comparison enables the measuring instrument to make more precise results.

The most elementary procedure is to employ a list of Accredited gages blocks. These are usually built to nationwide expectations. In general, they have a thickness of 1 mm plus a diameter of sixty three mm.

Applying these gages, you ought to evaluate A variety of hundreds. Usually, you should have 5 to 10 exam points. By way of example, chances are you'll measure displacement, internal tension, and corner radius.

During calibration, you'll want to document the result that will help you figure out what to do future. You can even make use of automated workflows to retrieve and examine knowledge.

To accomplish this, You'll need a good calibration prepare. A properly-penned system will describe the actions associated with the calibration method. It'll include things like the efficiency specifications you'll use, the solutions and resources utilised, and the reasons with the calibration.

Accreditation

If you're Performing to supply top quality items, You'll have to calibrate your applications. This method is essential to make sure the precision of one's items and procedures. You can utilize a certified calibration company provider to satisfy your necessities.

Accredited laboratories demonstrate their technological and tests competence. Accreditation also delivers assurance that the lab is independently confirmed by a third party.

The scope of accreditation defines the parts of the laboratory and the categories of measurements it truly is able to carrying out. What's more, it describes the sort of apparatus that is definitely employed. An accrediting body will usually evaluate the caliber of a lab's surroundings and staff.

The calibration laboratory is anticipated to follow a rigid list of necessities. These include the security of the personnel along with the surroundings. A danger administration technique is also required.

ISO/IEC/EN 17025 is a global common for quality. It requires a Homepage danger management procedure and an intensive audit from the lab. On top of that, the calibration laboratory is needed to own a quality assurance plan.

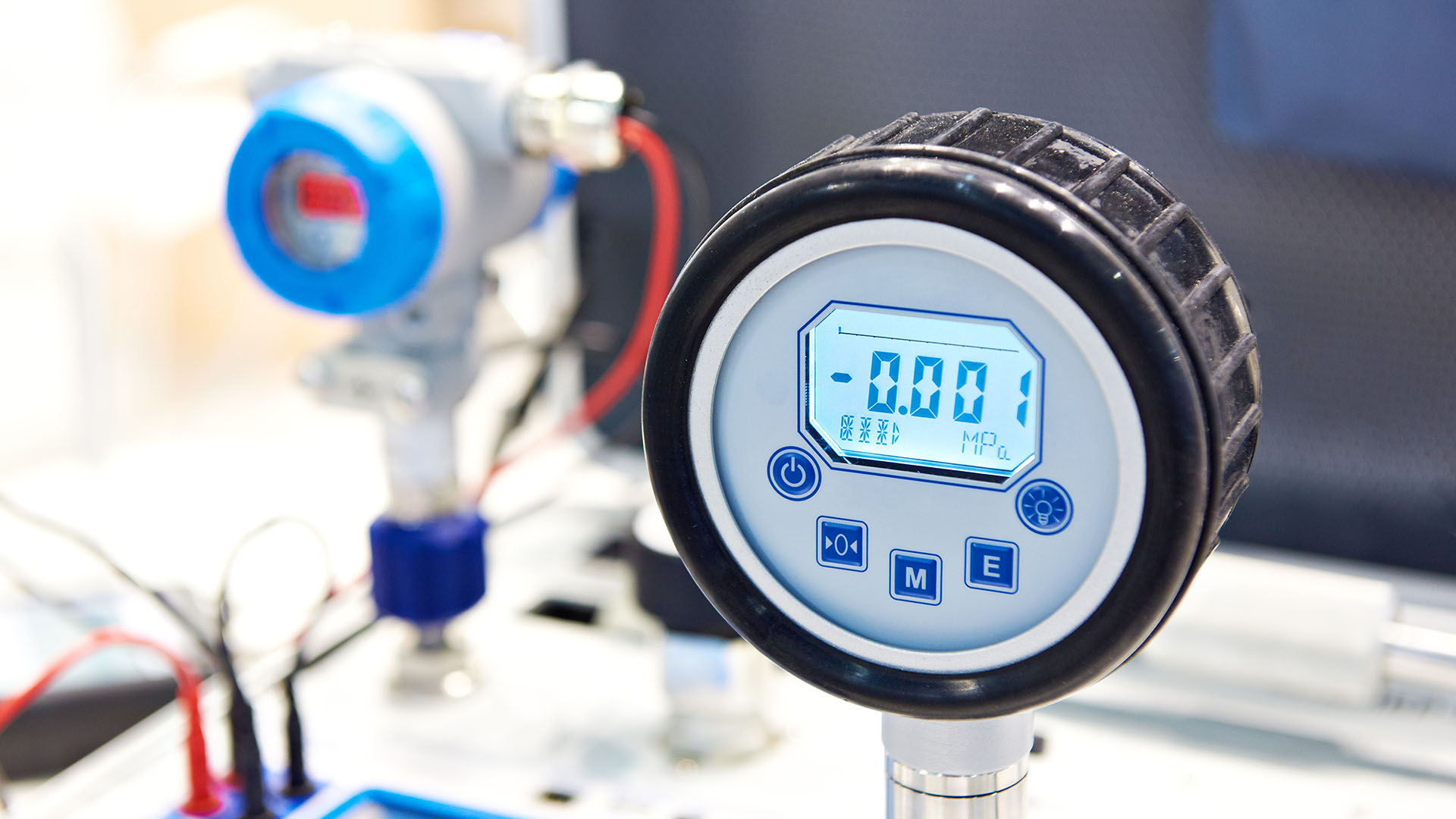

Bench calibration

If your bench calibration Resource has to be recalibrated, it is vital to understand how to properly accomplish the process. This could be certain that the measurement is traceable on the Nationwide Institute of Specifications and Know-how (NIST) regular.

Calibration is step one to retaining the performance of one's measurement equipment. It is also the only way to guarantee the accuracy of one's gear.

Bench calibration involves disconnecting your instrument from the procedure it really is measuring, cleansing it, and afterwards mounting it on the exam stand. To be powerful, the procedure really should be carried out within a controlled environment.

A managed ecosystem helps you to decrease the overall uncertainty and the potential risk of mistakes. The bench must have use of a pressure supply. Typically, this is a hand pump. In addition, the gauge need to be mounted in exactly the same orientation as the method.

In order to thoroughly calibrate your bench scale, You'll have a reference pressure gauge which might be traced again to the producer. On the whole, you'll be able to anticipate the traceable strain reference to acquire an accuracy of 4 times the precision of one's device.

Traceability

Traceability is the whole process of connecting the outcome of the calibration for the founded specifications. That is a way to reduce danger associated with measurement machines and the devices accustomed to measure.

The National Institute of Specifications and Technology (NIST) has long been acquiring technical info on traceability. NIST also gives certifications for reference materials and measurement protocols. In addition, it conducts coordinated outreach programs on traceability.

The NIST High-quality Procedure for Measurement Expert services defines traceability as being the connection between the measurements and benefits of the calibration as well as the founded specifications. If the measurements are to be traced to NIST or to another regular, the Business have to adhere to examination processes and protocol.

Traceability can be a prerequisite to meeting the requirements of globally regulatory agencies. A good product could be useless if it has no assurance of accurate measurement. Moreover, it may induce large expenditures if it fails.

The initial step in traceability is to ascertain a series of reference. Utilizing the Worldwide Technique of Models, or SI, a Instrument need to be calibrated and its success are then verified and accepted.