You will find there's method that's useful for recalibrating a Instrument and it is called bench calibration. It is an important procedure that needs to be executed if you want to make certain that the entire elements of a Resource are functioning appropriately. If a Instrument isn't effectively re calibrated, it may result in inaccurate measurement. This may result in many different challenges.

Basic process

There are various measures linked to the entire process of recalibrating a Software. Calibration involves evaluating an instrument's output having a reference instrument's. This comparison permits the measuring instrument to generate additional precise outcomes.

The most basic treatment is to work with a list of Accredited gages blocks. These are frequently manufactured to nationwide requirements. On the whole, they have a thickness of 1 mm along with a diameter of 63 mm.

Employing these gages, you must evaluate a range of masses. Usually, you will have 5 to 10 exam points. Such as, you could evaluate displacement, inner pressure, and corner radius.

All through calibration, you'll want to history the result to assist you to identify what to do upcoming. You can also make the most of automatic workflows to retrieve and assess knowledge.

To achieve this, You will need a fantastic calibration prepare. A perfectly-composed system will reveal the techniques involved in the calibration method. It'll incorporate the effectiveness requirements you are going to use, the approaches and resources applied, and the reasons for the calibration.

Accreditation

Should you be onsite calibrations Doing work to make top quality products, You'll have to calibrate your equipment. This method is essential to ensure the precision of the goods and procedures. You may use a Licensed calibration support supplier to satisfy your needs.

Accredited laboratories demonstrate their technical and testing competence. Accreditation also supplies assurance which the lab is independently verified by a 3rd party.

The scope of accreditation defines the regions of the laboratory and the categories of measurements it is actually effective at carrying out. In addition, it describes the type of apparatus that may be employed. An accrediting system will commonly assess the standard of a lab's ecosystem and staff.

The calibration laboratory is predicted to observe a stringent list of necessities. These involve the safety of your personnel as well as natural environment. A chance management method is additionally expected.

ISO/IEC/EN 17025 is a worldwide conventional for good quality. It requires a threat administration system and a radical audit with the lab. Moreover, the calibration laboratory https://en.wikipedia.org/wiki/?search=calibration is needed to have a top quality assurance software.

Bench calibration

If your bench calibration Resource must be recalibrated, it is necessary to know how to properly carry out the process. This tends to make certain that the measurement is traceable on the National Institute of Criteria and Technologies (NIST) typical.

Calibration is the initial step to maintaining the effectiveness within your measurement gear. It is also the sole way to guarantee the precision of one's gear.

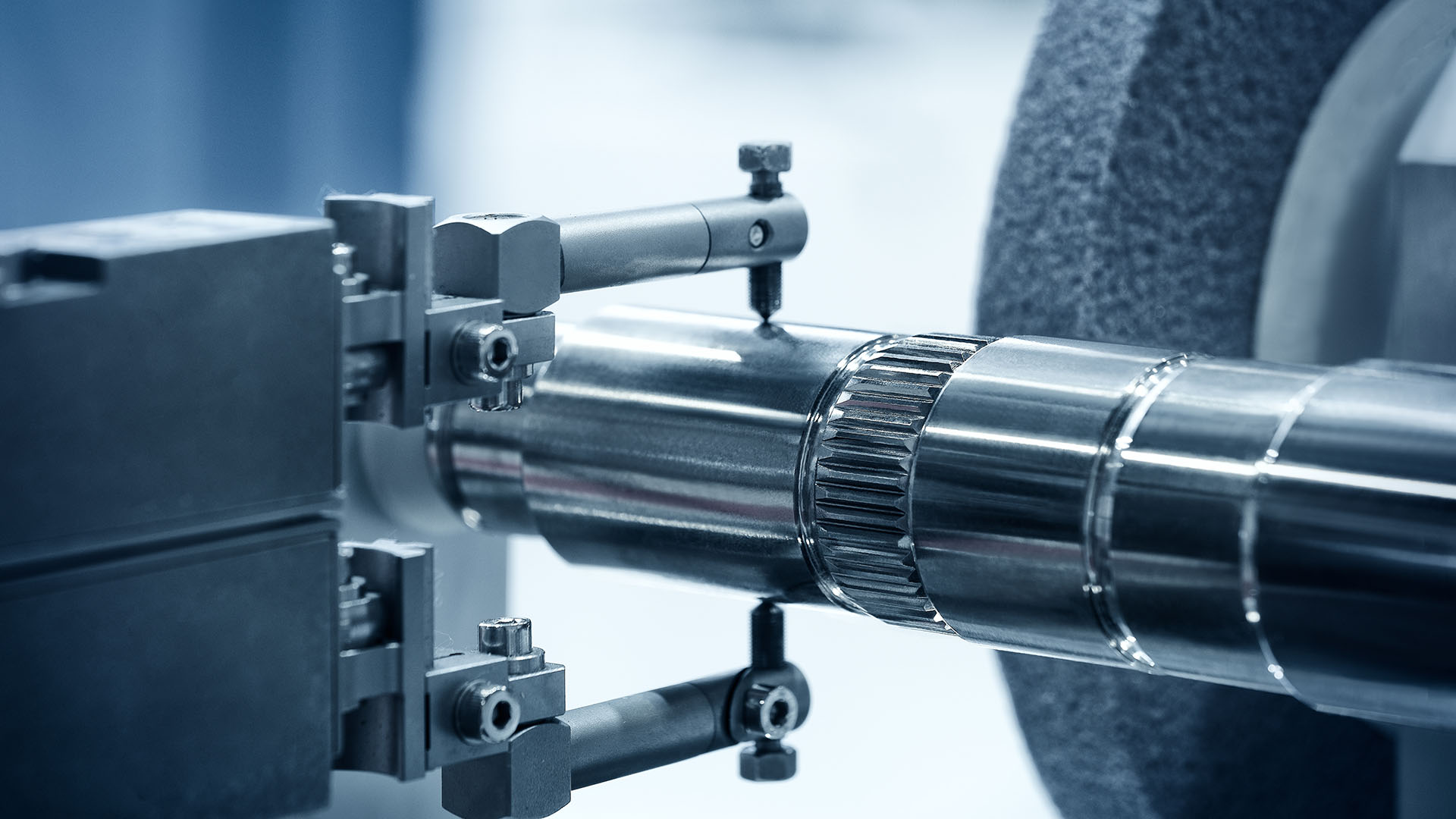

Bench calibration includes disconnecting your instrument from the process it's measuring, cleaning it, after which mounting it on a check stand. To get helpful, the procedure ought to be accomplished in the controlled surroundings.

A controlled environment helps to lessen the complete uncertainty and the potential risk of faults. The bench should have usage of a strain resource. Normally, this can be a hand pump. Furthermore, the gauge need to be mounted in the identical orientation as the method.

To be able to effectively calibrate your bench scale, You will need a reference tension gauge which might be traced again to the producer. Usually, you can count on the traceable force reference to get an precision of four moments the precision of your respective gadget.

Traceability

Traceability is the whole process of connecting the effects of the calibration towards the recognized requirements. This can be a way to reduce possibility affiliated with measurement machines and the devices accustomed to evaluate.

The Nationwide Institute of Standards and Technological know-how (NIST) has become establishing specialized information on traceability. NIST also offers certifications for reference resources and measurement protocols. In addition it conducts coordinated outreach plans on traceability.

The NIST Top quality Technique for Measurement Products and services defines traceability since the link involving the measurements and effects of the calibration along with the recognized specifications. Whether the measurements are to get traced to NIST or to a unique typical, the organization must stick to exam strategies and protocol.

Traceability is actually a prerequisite to meeting the necessities of worldwide regulatory agencies. A superb product can be worthless if it's got no assurance of precise measurement. Additionally, it might trigger significant expenditures if it fails.

The initial step in traceability is to establish a sequence of reference. Using the Worldwide Method of Units, or SI, a tool needs to be calibrated and its success are then verified and recognized.